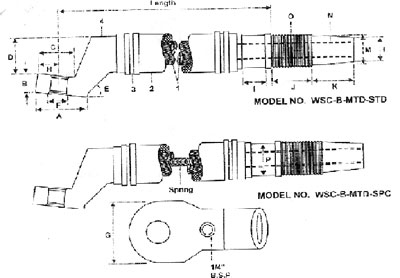

TERMINALS

Straight lugs are machined from high conductivity electrolytic Copper bar stock.

Bends lugs are forged and machine from high conductivity electrolytic copper.

WIRE CONSTRUCTION

This is a made from 0.05mm2 electrolytic grade Copper wire. Each bunch or herringbone construction to reduce the rate of wire facture by providing lateral surfaces wears areas. The total sectional area shall not be less than the sectional area as per MCM/mm2 rating.

WIRE CONNECTION TO TERMINAL

Water is terminated in a crimped in soft electrolytic tube and the soldered to the terminals.

Wire cannot melt out during brief overloads

FLEXIBLE HOSE COVER

The outer rubber hose made of heat resistant on its inner Surfaces & abrasion resident on its outer surfaces.

WATER FLOW

Coiling water is passed at the rate of 3 lit/ min at the pressure of the 6kgf/ cm2 and the pressure drop does not exceed 0.7kg/ cm2

WATER PRESSURE

The cable is tested at a pressure of 6 kgf/ cm2 (kcs) to ensure then there is no leakage or hose damage.

OPTIONAL FEATURE

ROTECTION SLEEVES : - In order to eliminate breakage of strands due to frequent acute bending operation, projection sleeves are provided on the area of both the terminal joints. |